Rigid Polyurethane System for Wood Imitation

Products Introduction

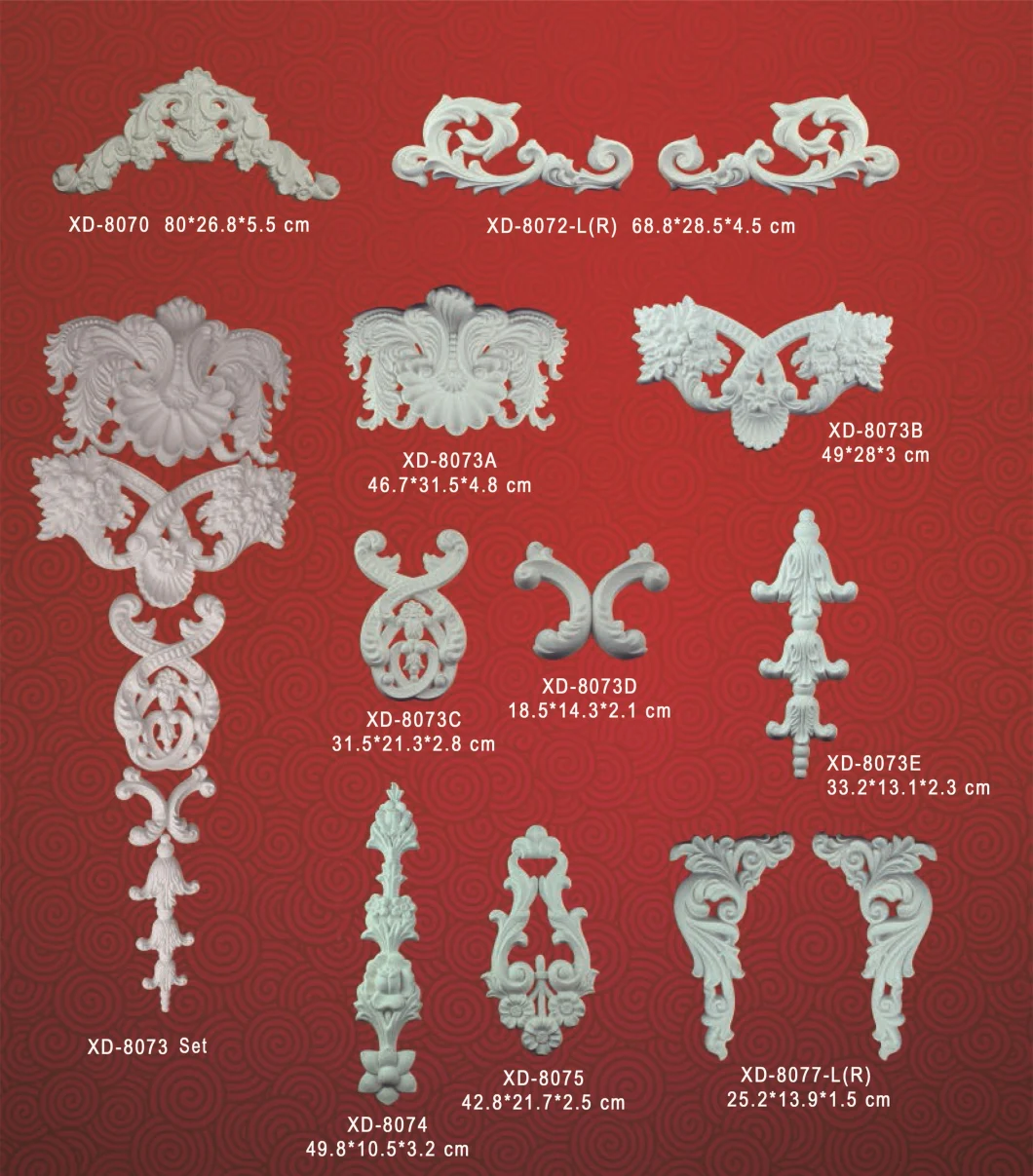

"Wood Imitation" structure foam , is a new type of carving synthetic materials. It has high mechanical strength and hardness, simple molding process , high production efficiency and excellent appearance.

Characteristics are as follows,

1. excellent repetition molding property. It not only can mould certain shape size, but also mould lifelike wood texture and other designs, good feel of touch

2. appearance and feel close to wood , which could be planed, nailed, drilled, and carved patterns or designs .

3. mould can only be produced using aluminum or steel, but can use silicon rubber, epoxy resin or other resin, which are low cost and easy machining.

4. process is simple, fast, high efficiency of qualified.

5. physical and mechanical properties is one of optimal synthesis wood produced by various polymer . Physical property can be controlled by adjusting the formula.

Physical Property

| Appearance Hydroxyl value mgKOH/g Viscosity 25°C mPa.s Density 20 °C g/ml Storage temperature Storage stability Month | Light yellow to brown yellow viscous liquid 250-400 600-1000 1.10±0.02 10-25 6 |

Recommended Ratio

| pbw | |

| LY-1005 polyols Isocyanate | 100 100-105 |

Foam Performance

| Moulding density Curving strength Compressive strength Tensile strength Surface strength shrinking ratio | Kg/m3 MPa MPa MPa Shore D % | 300-600 7-20 10-20 10-25 50-80 ≤0.3 |

4. packing

New steel drums,IBC drums,in bulk or Isotank.

5. Hanlding

Contact with skin and eyes must be avoided. Safety goggles, protective gloves and overalls must be worn when working with these chemicals.

6. Storage

The materials are sensitive to humidity and partially used drums should be tightly sealed to prevent the ingress of moisture.

(Polyol Blend)

The Polyol blend has a shelf life of three to six months from date of manufacture when stored indoors at temperatures of 20-30°C. The Polyol blend is recommended thoroughly mixed before using.

(Isocyanate)

The Isocyanate has a shelf life of one year from date of manufacture when stored indoors at temperatures of 20-30°C. Avoid storage temperatures of below 0°C (as some crystallization may occur) or above 50°C (as formation of insoluble solids may occur).