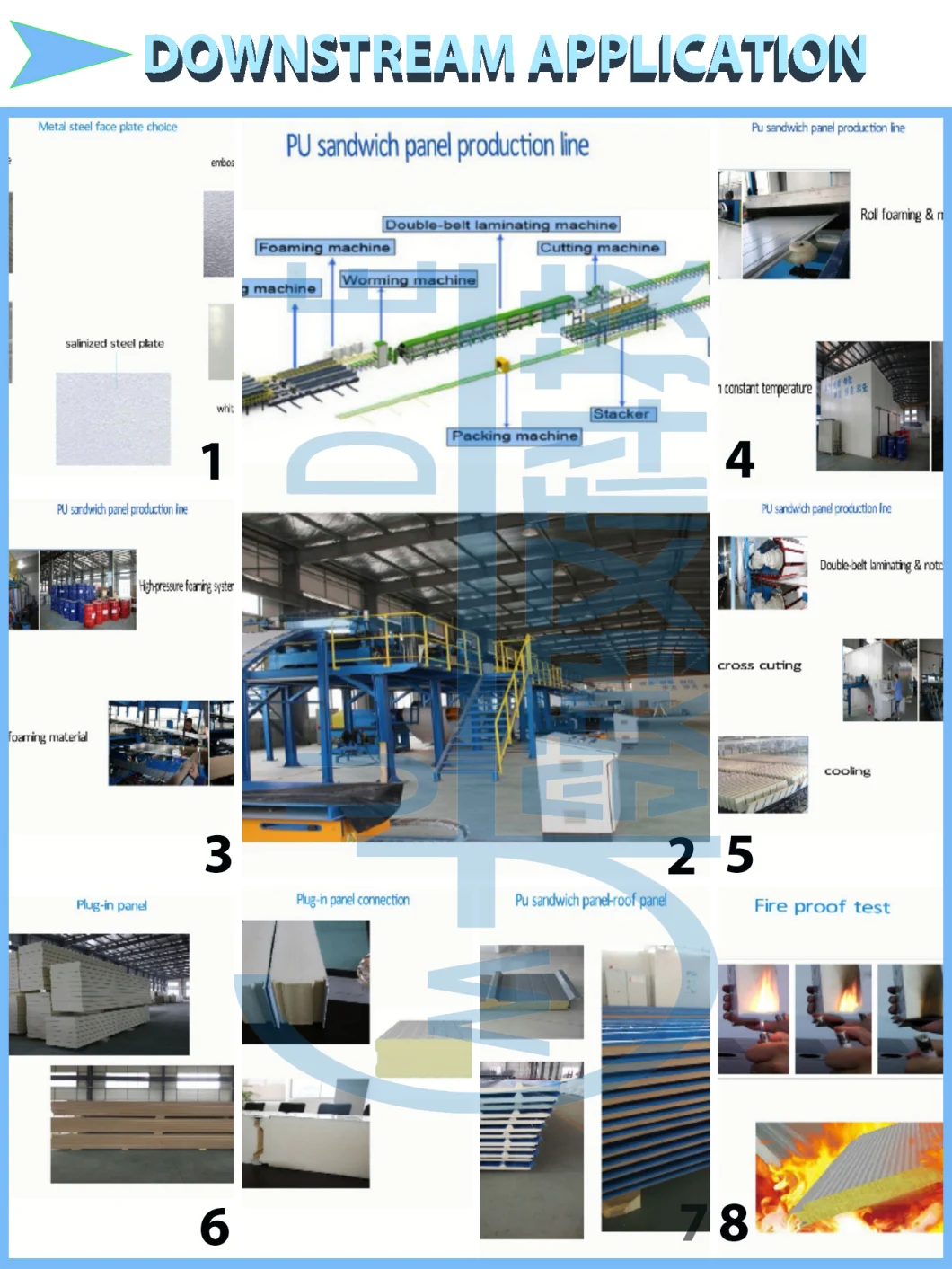

PRODUCT DESCRIPTION

LYR1795 is a fully blended system including HCFC141b and a fire retardant. It is designed

for processing using a continuous lamination machine. Moulded densities will be 35-40 kg/m³.

This system is designed to meet DIN 4102 Class B2.

LYR1795 is a fully blended system including HCFC141b and a fire retardant. It is designed

for processing using a continuous lamination machine. Moulded densities will be 35-40 kg/m³.

This system is designed to meet DIN 4102 Class B2.

CHEMICAL PROPERTIES

LYR1795 A(Polyol Blend)

| Appearance | Brown Liquid |

| Specific Gravity @25°C | 1.19 - 1.21 |

| Viscosity @25°C | 180 - 260 mPas |

LYR1795 B (Isocyanate)

| Appearance | Dark Brown Liquid |

| Specific Gravity @25°C | 1.22 - 1.26 |

| Viscosity @25°C | 150 - 250 mPas |

TYPICAL REACTION DATA

Laboratory

| Mixing Ratio (A : B) | / |

| Chemical Temperatures (°C) | / |

| Cream Time (s) | / |

| Gel Time (s) | / |

| Free Rise Core Density (kg/m )3 | / |

TYPICAL PHYSICAL PROPERTIES

| Property | Test Standard | Unit | Value |

| Overall Moulded Density | - | kg/m3 | 40 |

| Core Density | - | kg/m3 | 36 |

| Compressive Strength - Parallel - Perpendicular | ASTM D1621 | kPa | 202 186 |

| Dimensional Stability 48 hours exposure @ -15°C @100°C | ASTM D2126 | % volume change | 0.1 2.6 |

| Thermal Conductivity | ASTM C518 | W/m°C | 0.0194 |

STORAGE OF MATERIALS

The materials are sensitive to humidity and partially used drums should be tightly sealed to

prevent the ingress of moisture.

LYR1795A (Polyol Blend)

The Polyol blend has a shelf life of three months from date of manufacture when stored indoors

at temperatures of 20-30°C. The Polyol blend should be thoroughly mixed before use.

LYR1795B (Isocyanate)

The Isocyanate has a shelf life of one year from date of manufacture when stored indoors at

temperatures of 20-30°C. Avoid storage temperatures of below 0°C (as some crystallization

may occur) or above 50°C (as formation of insoluble so lids may occur).