Manufacture Process:

1.Review the part design,drawings and quality standard from clients.

2. Mould and Tooling design & manufacturing

3. Mould and Tooling testing & confirm the sample

4. Die casting raw castings

5.Surface treatment: Trimming,Deburring, polishing, cleaning, passivation & power coating and other, requirement from Customer

6. Precision machining: CNC lathes, milling, drilling, grinding etc

7. Full Inspection

8. Packing

9. Delivery

Advantages:

1. Competitive price

2. Strict quality control system

3. Quick mold making and delivery

4. Advanced equipment, excellent R&D teams

5. Have accumulated many years of Moulding experience of 20 years, with professional andtechnical personnel and skilled workforce

Special info:

Following customers' requirement to make the molds.

Mold base: LKM C50 standard mould molds

Inserts(cavity and core): Dievar, H13, 8407, 1.2344 or the material you required.

Standard parts: HASCO, DME, MISUMI, Punch

Part material: ADC12, ADC14, ADC10, A413.2, A360, A380, AlSi9Cu3, ZAMAK#3, ZAMAK#5, ZAMAK#2, ZAMAK#8, PC,PA,ABS,PVC,PA66,TPE,SAN,POMand so on

Lead time of first samples: Around 3~5weeks.

Service:

1. OEM and ODM.

2. Quotation within 24 hours.

3. Inspection service by SGS or any other inspection assigned by Customer.

4. Shipping service.

5. After service

Why choice us:

1.Senbao is a precision hardware processing manufacturer with nearly 20 years of experience.With experience technical team ensure us being able to offer the service with International standard towards to our customers.

2.It is known for its fast production, OEM and personalized customization.It is expert at Strong R&D strength, exquisite workmanship, products of various materials and complex shapes.

3.Rely on International tooling designing concept and manufacturing,we could build tailor-made tool to satisfy with your products quality requirement.

4.Equipped unique with top performance die casting machines and CNC machines, give us the possibility to produce high precision products.

5.The strong application technical support towards the customer in project development phase which difference from the other suppliers. From the drawing design, production, inspection, process layer upon layer check, To exceed the industry standard, Propose feasible improvement plan for the product structure, reduce the cost, and make the customer's product more competitive in the market. Our mission is building long term co-operation with our customers.

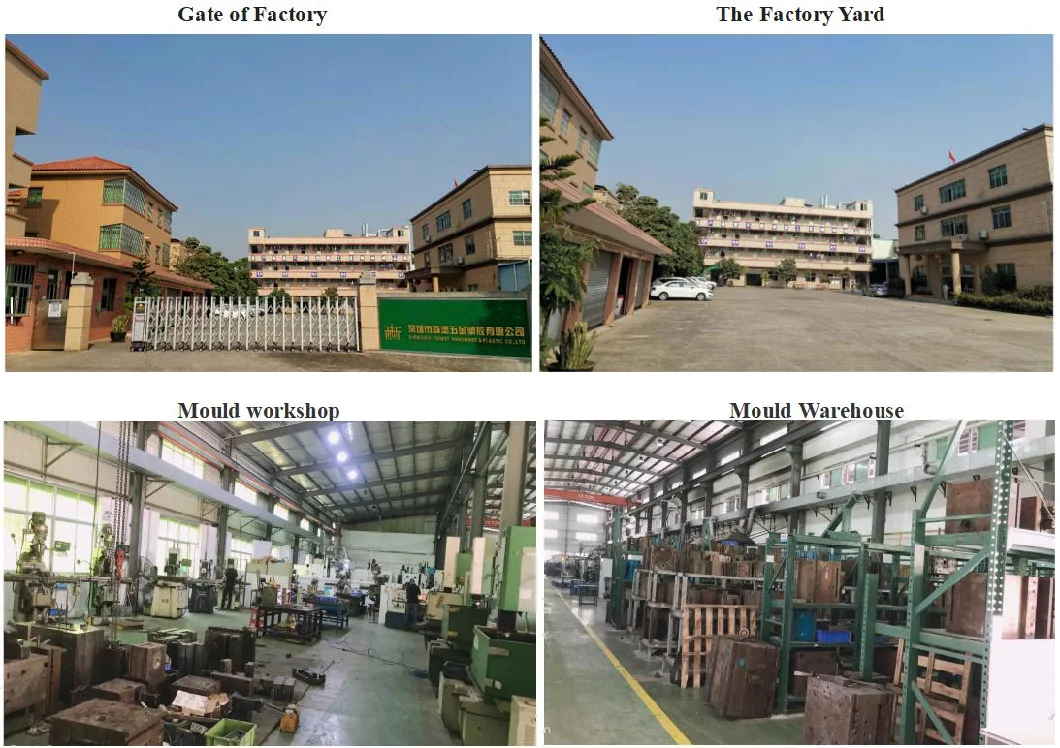

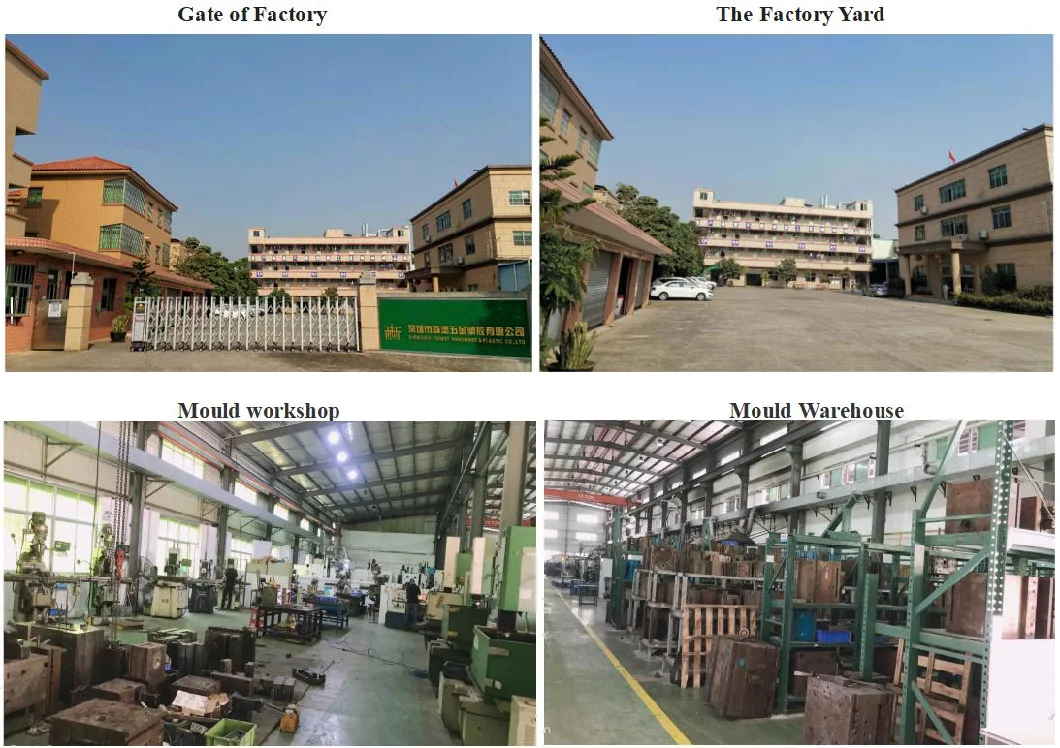

Factory

The total area of the factory is about 10,000 square meters, and it has been invested about 30 million RMB. seven Aluminum alloy die-casting machine (280-800 tons) , four Zinc alloy die-casting machine (88-280 tons) . There are more than 30 high precision mould manufacturing equipment (six CNC machining center , six spark machine of wire cutting, six computer milling machine, and a variety of auxiliary equipment) . Besides that , more than 30 high precision CNC machining centers, and more than 50 sets of carving machines, CNC lathes, drilling machines, tapping machines, polishing machines and printing machines are prepared.

Inspection Equipment

inspection equipment include:2.5 dimensional measuring instrument, 3 dimensional measuringinstrument, universal tensile testing machine, 2 dimensional height instrument, salt spray testing machine, projector, hardness tester, pass gauge, parallel instrument, various calipers, tool microscope, ring gauge, chromatic aberration instrument and other high-end testing instruments and equipment.

Inspection item: coating thickness test, roughness test, pass-stop test, salt spray test, full-scale

inspection and test report.

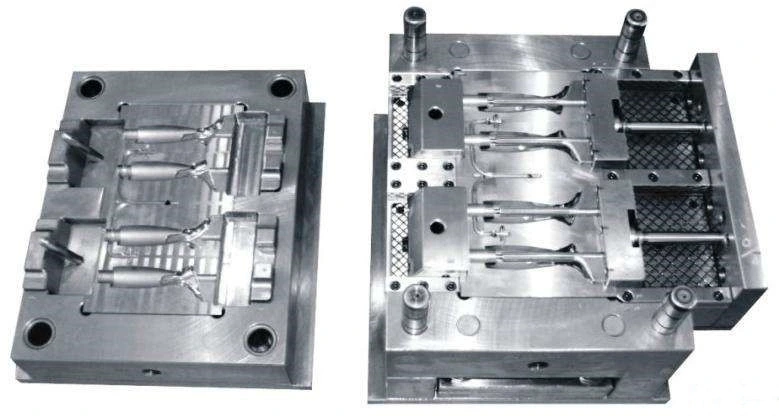

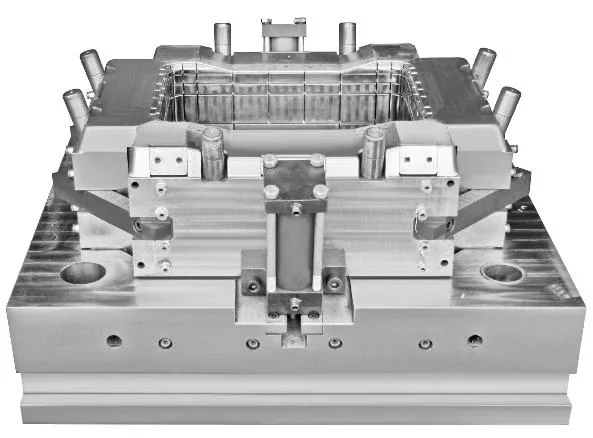

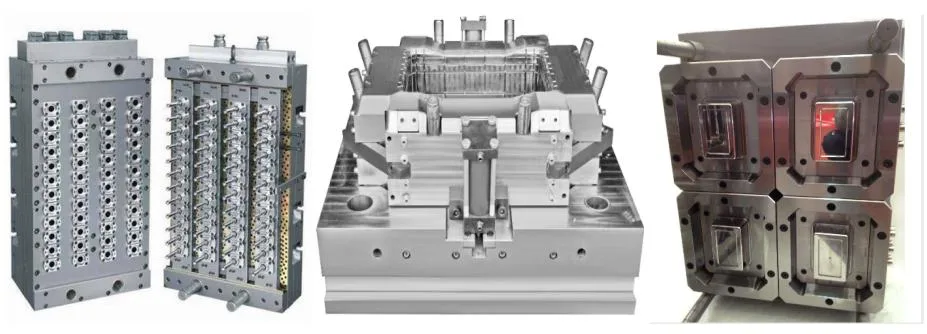

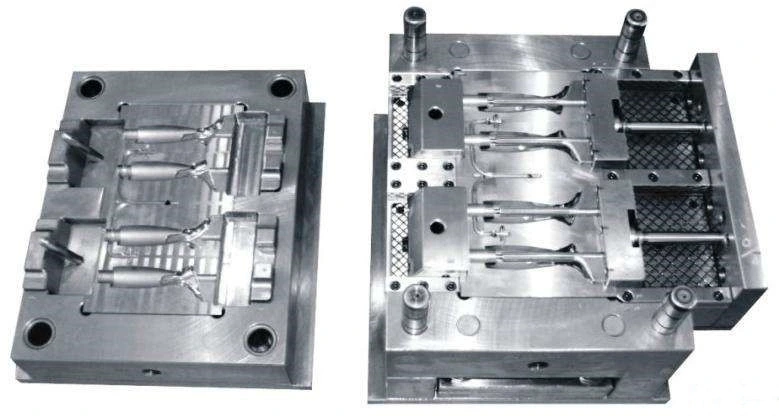

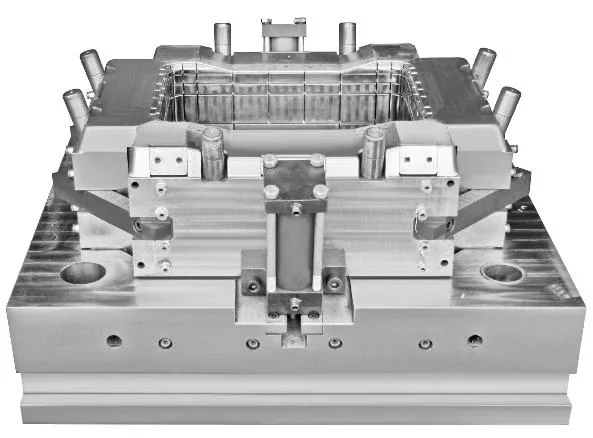

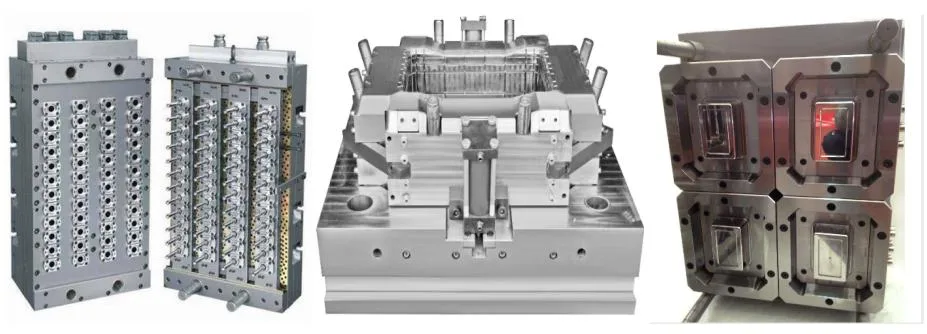

Moulds

Senbao will maximize the net shape and tolerances into the mold, thus reducing the cost of secondary processing. The international standard mold steel materials H13 and H718 adopted by Wing can effectively improve the life and part quality of the mold, and ensure the mold operation during mass production.

Products

Aluminum Die Casting

In the pressure Aluminum Die Casting process the metal is forced into a high grade steel tool at high speed and pressure. The casting temperature is roughly 700°C when you do Aluminum Die Casting.

Our products are abroad applied for various design and sizes parts for all types of industries such as electrical appliances, aerospace, microwave communication, optical equipment, lighting industry, measuring instruments, automation equipment, medical equipment, household appliances, digital products, automobile industry, security products, sporting goods, health supplies, etc.

Packing

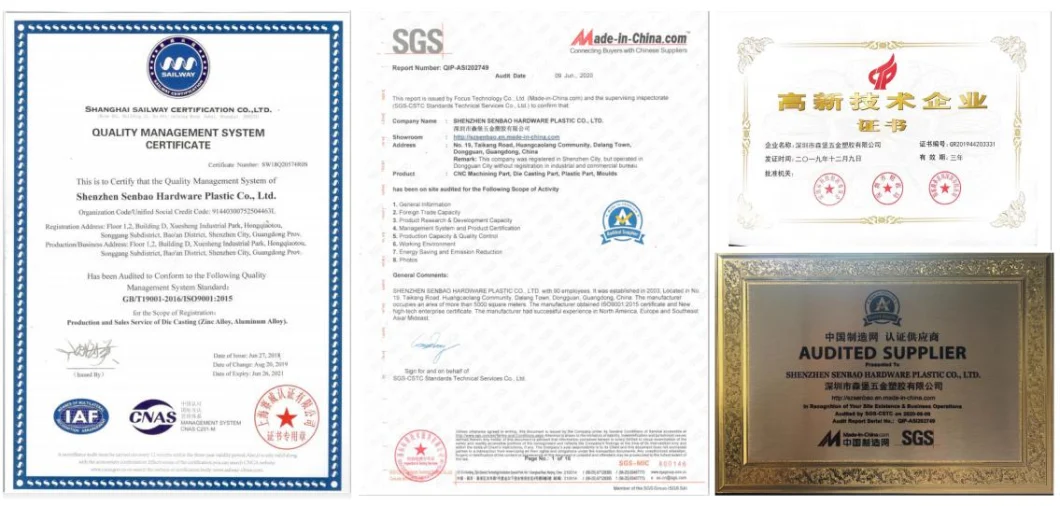

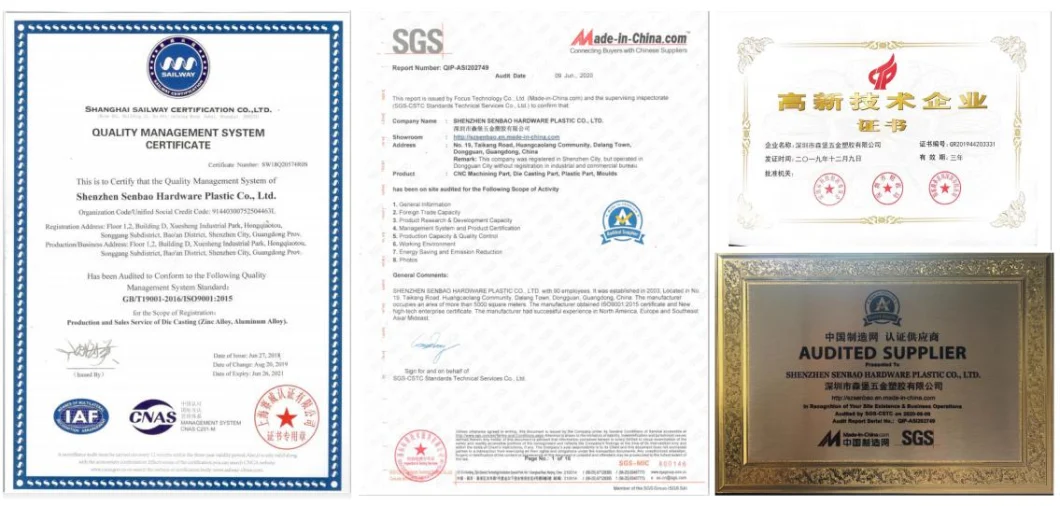

Certificates

1.Review the part design,drawings and quality standard from clients.

2. Mould and Tooling design & manufacturing

3. Mould and Tooling testing & confirm the sample

4. Die casting raw castings

5.Surface treatment: Trimming,Deburring, polishing, cleaning, passivation & power coating and other, requirement from Customer

6. Precision machining: CNC lathes, milling, drilling, grinding etc

7. Full Inspection

8. Packing

9. Delivery

Advantages:

1. Competitive price

2. Strict quality control system

3. Quick mold making and delivery

4. Advanced equipment, excellent R&D teams

5. Have accumulated many years of Moulding experience of 20 years, with professional andtechnical personnel and skilled workforce

Special info:

Following customers' requirement to make the molds.

Mold base: LKM C50 standard mould molds

Inserts(cavity and core): Dievar, H13, 8407, 1.2344 or the material you required.

Standard parts: HASCO, DME, MISUMI, Punch

Part material: ADC12, ADC14, ADC10, A413.2, A360, A380, AlSi9Cu3, ZAMAK#3, ZAMAK#5, ZAMAK#2, ZAMAK#8, PC,PA,ABS,PVC,PA66,TPE,SAN,POMand so on

Lead time of first samples: Around 3~5weeks.

Service:

1. OEM and ODM.

2. Quotation within 24 hours.

3. Inspection service by SGS or any other inspection assigned by Customer.

4. Shipping service.

5. After service

Why choice us:

1.Senbao is a precision hardware processing manufacturer with nearly 20 years of experience.With experience technical team ensure us being able to offer the service with International standard towards to our customers.

2.It is known for its fast production, OEM and personalized customization.It is expert at Strong R&D strength, exquisite workmanship, products of various materials and complex shapes.

3.Rely on International tooling designing concept and manufacturing,we could build tailor-made tool to satisfy with your products quality requirement.

4.Equipped unique with top performance die casting machines and CNC machines, give us the possibility to produce high precision products.

5.The strong application technical support towards the customer in project development phase which difference from the other suppliers. From the drawing design, production, inspection, process layer upon layer check, To exceed the industry standard, Propose feasible improvement plan for the product structure, reduce the cost, and make the customer's product more competitive in the market. Our mission is building long term co-operation with our customers.

Factory

The total area of the factory is about 10,000 square meters, and it has been invested about 30 million RMB. seven Aluminum alloy die-casting machine (280-800 tons) , four Zinc alloy die-casting machine (88-280 tons) . There are more than 30 high precision mould manufacturing equipment (six CNC machining center , six spark machine of wire cutting, six computer milling machine, and a variety of auxiliary equipment) . Besides that , more than 30 high precision CNC machining centers, and more than 50 sets of carving machines, CNC lathes, drilling machines, tapping machines, polishing machines and printing machines are prepared.

Inspection Equipment

inspection equipment include:2.5 dimensional measuring instrument, 3 dimensional measuringinstrument, universal tensile testing machine, 2 dimensional height instrument, salt spray testing machine, projector, hardness tester, pass gauge, parallel instrument, various calipers, tool microscope, ring gauge, chromatic aberration instrument and other high-end testing instruments and equipment.

Inspection item: coating thickness test, roughness test, pass-stop test, salt spray test, full-scale

inspection and test report.

Moulds

Senbao will maximize the net shape and tolerances into the mold, thus reducing the cost of secondary processing. The international standard mold steel materials H13 and H718 adopted by Wing can effectively improve the life and part quality of the mold, and ensure the mold operation during mass production.

Products

Aluminum Die Casting

In the pressure Aluminum Die Casting process the metal is forced into a high grade steel tool at high speed and pressure. The casting temperature is roughly 700°C when you do Aluminum Die Casting.

Our products are abroad applied for various design and sizes parts for all types of industries such as electrical appliances, aerospace, microwave communication, optical equipment, lighting industry, measuring instruments, automation equipment, medical equipment, household appliances, digital products, automobile industry, security products, sporting goods, health supplies, etc.

Packing

Certificates

| FAQ |

| 1: What are our Advantages over others? a).We are the Manufacture,not a trading company, less cost purchase, competitive price. b).Senbao is a precision hardware processing manufacturer with nearly 20 years of experience. f).During our cooperation: We have QC department,Sales department,Engineer department, Shipping department.,After-Sales,Department, to serve you all the time. |

| 2. Can you sent the product drawing to me? Pictures on website was just for reference, More correct information and some special requirements, Please kindly contact us. |

| 3. Can you make OEM order? Yes, OEM/ODM orders are welcome. You are warmly welcome to send the your designs to us, We will offer you reasonable prices with high quality Please provide us the drawings or please tell us the detailed information what you need, we can copy the parts according to your information. |

| 4. How long can I expect to get the sample? Samples will be ready for delivery in 3-10 days after we confirmed the shop drawings, The samples will be sent to you via express and arrive in 3-5 days. |

| 5. What about the lead time for mass production? Honestly, normally it is 15-30 days, and it depends on the order quantity and the season you place the order. Generally speaking, (if you project is urgent, we can help you short it), we suggest that you start inquiry one months before the date you would like to get the products at your country. |

| 6. What are your terms of delivery? We accept EXW, FOB, CNF, etc. You can choose the most convenient one. Regarding to the shipping cost, if you have your own express account that will be welcome. |